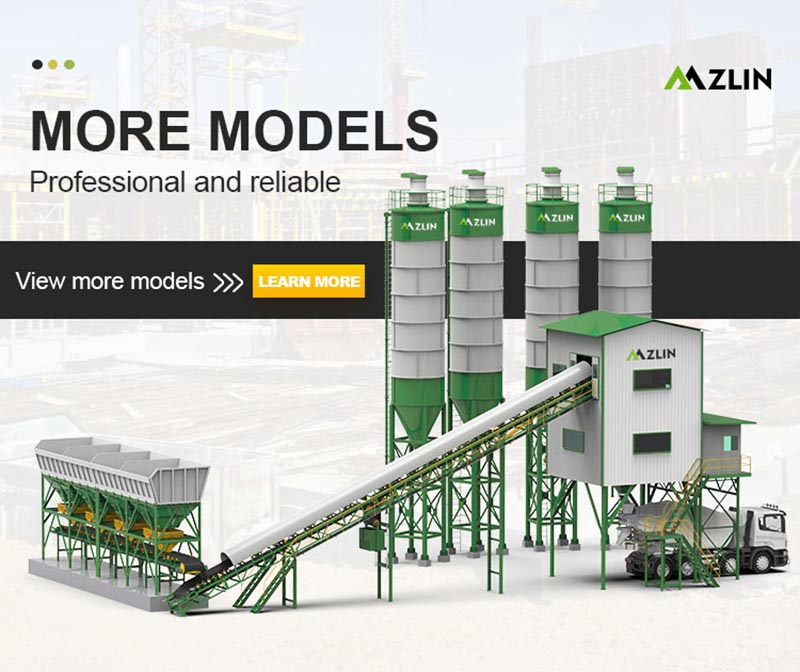

Stationary concrete batching plant mixes cement, sandstone, limestone, coal, and other raw materials to make concrete which is widely used in construction projects. Generally speaking, stationary batching plant is used in concrete engineering, all-sized construction projects, water conservancy, bridges, and tunnels for their high productivity, convenient operation, and high working efficiency.

According to the aggregate feeding method, the fixed concrete batching plant can be divided into two types: Skip hoist type and belt conveyor type.

The production capacity of the Skip hoist type concrete batching plant can reach 25/35/50/75 m3/h, and the production capacity of the belt conveyor type concrete batching plant can reach 60/90/120/180/240 m3/h.

| HZS25 Fixed | HZS35 Fixed | HZS50 Fixed | HZS75 Fixed | |

| Max.productivity | 25m3/hr | 35m/hr | 50m/hr | 75m/hr |

Standard discharge height | 2m | 2m | 3.8m | 3.8m | |

aggregate conveying type | Skip hoist type | ||||

control type | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | |

| Model | JS500 | JS750 | JS1000 | JS1500 |

Working cycle time | ≥60 | ||||

Stirring motor power | Y180M-4 | Y200L-4 | Y180M-4 | Y180L-4 | |

| Model | PLD800 | PLD1200 | PLD1600 | PLD2400 |

Batchable number of aggregate | 2 | 2-3 | 2-4 | 3-4 | |

Hopper capacity | 2 | 2 | 2 | 3 | |

Feeding height | 2.3m | 2.8m | 3m | 3.2m | |

| HZS25 Fixed | HZS35 Fixed | HZS50 Fixed | HZS75 Fixed | |

| Max.productivity | 25m3/hr | 35m/hr | 50m/hr | 75m/hr |

Standard discharge height | 2m | 2m | 3.8m | 3.8m | |

aggregate conveying type | Skip hoist type | ||||

control type | Manual / Auto | Manual / Auto | Manual / Auto | Manual / Auto | |

| Model | JS500 | JS750 | JS1000 | JS1500 |

Working cycle time | ≥60 | ||||

Stirring motor power | Y180M-4 | Y200L-4 | Y180M-4 | Y180L-4 | |

| Model | PLD800 | PLD1200 | PLD1600 | PLD2400 |

Batchable number of aggregate | 2 | 2-3 | 2-4 | 3-4 | |

Hopper capacity | 2 | 2 | 2 | 3 | |

Feeding height | 2.3m | 2.8m | 3m | 3.2m | |